Tuesday, June 17

Prevent Your Air Compressor from Overheating & Shutting Off in the Summer Heat

Summer heat brings out a ton of opportunities for compressor system failures and inefficiencies. It's critical to make sure your system is working properly through a hot summer. Just like we must take care of our bodies as temperatures rise, we also need to care for our compressors to avoid overheating and shutoffs.

Common Issues Brought on By Summer Heat & Solutions

While we hope your system never experiences overheating, we know that it may happen with extreme temperatures of Midwestern summers. The following are six common issues that can happen due to increased environmental temperatures and how you can mitigate these risks.

CLOGGED FILTERS & VENTS

Summer heat leads to increased contaminants in the air such as pollen and dust. These contaminants get caught in your system’s filters and since there are more contaminants in the summer, your vents and filters will become dirtier and clogged quicker. This causes your compressor to have to work harder as well.

WHAT YOU CAN DO

Filtration and ventilation are two major aspects that keep your compressed air efficiency high. Without air and oil being filtered correctly, the air compressor cannot produce consistent cool air to provide optimal performance. Check filters regularly for any contaminants that may have clogged them. If needed, clean or replace them immediately and continue to do so regularly.

Similarly, you should regularly inspect your air vents & HVAC system for any dust or dirt that needs to be cleared. Also make sure that your compressor room remains free from contaminants and is under a controlled temperature.

HIGHER MOISTURE LEVELS

When temperatures rise, air can hold more water vapor which means humidity increases. This means more moisture will be entering your compressed air system, possibly leading to water in your compressed air lines and moisture buildup in the tanks.

WHAT YOU CAN DO

If you are observing higher moisture levels that are affecting your system, make sure you are checking that your drains are functioning properly. Continue to check these drains more consistently and frequently during the warmer months. You will also want to check your air dryers as they work much harder in the summer.

Refrigerated air dryers require cleaning of their coils and maintaining refrigerant levels and circulation.

For desiccant air dryers you will need to change filters, inspect controls, and replace any contaminated desiccant materials frequently. If your system does not have an air dryer but is consistently seeing excess moisture, you should invest in an air dryer for your system.

Contact Zorn Compressor & Equipment to discuss the right options for you.

FAILED COMPONENTS

Since many components now must work harder to compensate for the effect of raised temperatures and excess heat, damage may occur to crucial parts such as belts, seals, and couplings. Extreme heat can even cause cracking of these components.

WHAT YOU CAN DO

Staying on top of your maintenance inspections is key to all components running smoothly. This is even more crucial during the summer months. Check any rubber parts for cracks and tears and make sure to replace any components as soon as wear and tear is visible. Common pain points include belts, seals, gaskets, and couplings.

LUBRICANT & OIL DEGRADATION

Hot temperatures cause more aggressive oil & lubricant break down. Since lubricants and oil are used to ensure smooth functioning of compressor components, their breakdown can cause excessive wear and tear to your entire system. Increased heat causes lubricants to thin and oils to degrade at a faster pace leading to increased friction in your machines. This also makes your system more prone to oil leaks.

WHAT YOU CAN DO

You will want to monitor your oil and lubricant levels regularly. In general, high heat can reduce your oil life by half of its normal lifespan- this means during the summer months you should be checking and/or changing your oil twice as often. Increase the number of your inspections of your system’s oil to find any dirt or contaminants that could degrade it.

LOWER FLOW RATES

Elevated temperatures mean lower density of the air around your system. With less dense air, a smaller volume is then drawn into the compressor leading to a decrease in horsepower and less air production in your facility.

WHAT YOU CAN DO

Aside from more frequent maintenance on your entire system, you may need to reevaluate the size of your system for your applications. With lower density, air needs to be compressed more than it usually would, causing your equipment to work harder. If this is a frequent issue, you may want to explore different sizing options.

OVERHEATING & SHUTOFFS

As a general rule of thumb, higher outside temperatures lead to increased temperatures in every aspect of your compressed air system. Air compressors already generate a lot of heat on their own, so when they are fed already hot temperatures, overheating is a common result. When a compressor overheats, many will automatically shut off to preserve the internal components and cool the system down. This may lead to a longer time for the system to be able to cool and turn back on, and it also decreases your whole plant’s efficiency until your system can be restarted.

If your compressor does not automatically shutoff, the excess discharge heat can cause many severe compressor failures such as

- Lubricant vaporization

- Melting of electrical components

- Destroyed insulation

- Decreased oil and motor life, and

- Eventually an entire compressor break down that can be unrepairable.

WHAT YOU CAN DO

There are a few ways you can prevent your air compressor from overheating.

First, improve the ventilation. This is especially crucial for compressors operating indoors during the warm months. You want to keep the room as cool as possible and vent hot air out of the area.

Next, you want to check your compressor’s coolers. Whether it is water or air cooled, you need to provide regular maintenance and cleaning to prevent overheating during the warm months. You will also need to clean the motor cabinet. This is an area that is constantly working hard and generating heat. Therefore, it is essential to clean and replace and parts in or surrounding this cabinet to allow it to filter and vent properly.

If you should reach the point of an automatic shutoff, do not force an immediate restart. Be patient and wait for your compressor to cool off completely before trying to turn it back on. If it continues to shut off, call your local Zorn Compressor & Equipment expert to assess the system and repair it. Too many shutoffs can lead to severe motor and electrical issues.

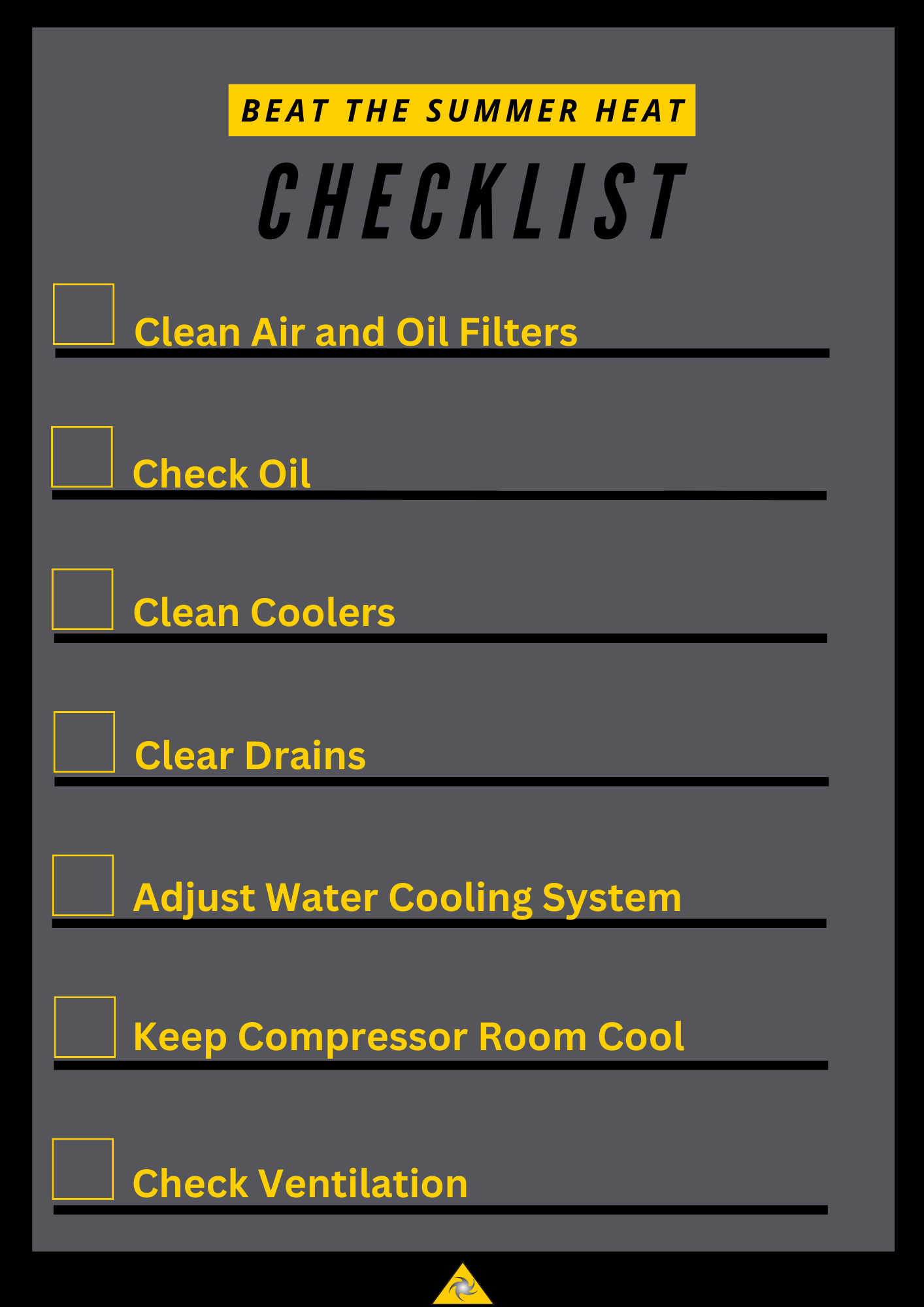

General Summer Air Compressor Maintenance & Ventilation Checklist

Leading up to and during summer, it's all about preventative maintenance and proper ventilation. Keeping these two aspects in mind, and the maintenance and ventilation checklists below, your compressed air equipment will continue running properly as the summer heat sets in. Here are the top things to make sure you cover to prevent overheating and shutoffs:

CLEAN AIR AND OIL FILTERS

Dirty filters can cause your compressor to overheat and perform at a much lower efficiency level. It is important to regularly clean oil and air filters and replace them as necessary to maximize your equipment longevity and uptime. Those with a heavy cottonwood population near their facility will want to pay special attention to cottonwood buildup in their filters, as this is a common pollutant we see with many of our customers.

CHECK OIL

During the hot summer months, it is critical to check your lubricant and test it for signs of degradation and change it if necessary. Lubricant is the life blood of your compressor. Heat is the largest factor in lubricant degradation. It also increases energy consumption and wear and operating temperature of the compressor.

CLEAN COOLERS

Make sure you clean your coolers so that they function properly, preventing your compressor from overheating. Remember to clean coolers consistently throughout the summer.

CLEAR DRAINS

You also need to clean the drains. More humidity means more condensate. Get ahead of any issues by checking the drains and clearing any blockages and fixing any issues with them. Just like with coolers, remember to check your drains regularly to make sure they are working properly. Otherwise, you'll be faced with condensate backup in your drains and bigger problems.

ADJUST WATER COOLING SYSTEM

When dealing with a water-cooled unit, make sure to adjust the temperature of your compressor’s inlet water. Monitor your compressor’s temperature levels throughout the summer to see if it requires a lower temperature setting to keep it from overheating.

KEEP THE COMPRESSOR ROOM COOL

Compressor room temperatures shouldn’t get to an ambient temperature above 100°F. If the ambient temperature is too high your compressors won’t run as efficiently and can overheat.

To keep the compressor room cool, you need proper ventilation and air flow to allow cool air in and there should be ducting to get the hot air out.

CHECK VENTILATION

Speaking of ventilation, equipment needs proper airflow. Just like everything else on this list, ventilation needs attention and maintenance throughout the summer months. It’s important to check the compressor room and adjust ventilation and airflow as needed.

ZORN'S PROMISE

Zorn is the Midwest leader of custom, engineered compressed air and vacuum solutions. We provide the best customer experience by understanding your applications and needs and offering an unparalleled commitment to customer satisfaction.

Our comprehensive product and service solutions keep you running 24/7.

- Reliable equipment

- Trusted brands

- Seamless, easy installation

- Post-sales support

- Local, 24/7 service

Our compressed air experts look forward to meeting you to discuss your equipment and support needs. Please contact us directly at (262) 695-7000 with any questions or to schedule service for your system moving forward.

Related Resources

- Spring Cleaning Checklist for Compressed Air Systems

- Air Compressor Dew Point 101

- Zorn Compressor Contractor Brochure

- Heat Recovery 101

- Air Compressor Applications in Toy Manufacturing

- How Industrial Air Compressors Are Different

- Trick or Treat: How Compressed Air Gives Us Halloween Candy!

- Technical Solutions Group

- Air Blowers 101

- Air Compressor Cooling Systems 101