Tuesday, March 26

Defining Compressed Air Quality

There is a major difference between high-quality compressed air and low-quality compressed air. While low-quality compressed air may be okay for some dirtier, industrial applications, many industries have strict air quality guidelines that need to be met. Let’s discuss compressed air quality and how to define it.

Defining Compressed Air Quality

The ambient air around us is full of contaminants like dust, moisture, and oil. When we compress this air, even more contaminants can be added into the mix, requiring a purification process to become clean air. There are three main contaminant types that may be present in the air:

Solid Particles: these can be dirt, dust, or other solid contaminants that are in the compressed air. Solid particles are measured by microns.

Moisture: water in liquid or vapor form can also be in the compressed air and cause contamination. This is measured by pressure dew point temperature and liquid water content.

Oil: liquid or vapor oil is the last type of contaminant that is commonly found in compressed air. Oil is measured in milligrams per cubic meter.

There are a few places contaminants originate from including the natural air surrounding the compressor, the various components contributing to the system (like the piping), and the mechanical moving processes that may create contaminants once the compression process has started.

Air Quality Classes: ISO 8573

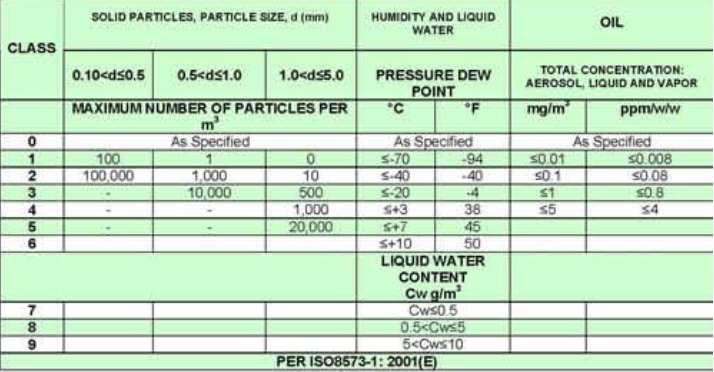

ISO 8573 is the group of international standards regarding the purity of compressed air. The first part classifies air quality levels and contaminant types, while parts two through nine define testing and measuring methods of contaminants in the air stream.

The three contaminant types listed above are used as the columns in a classification table of air quality. These classes range from class 0 to class 9, with class 0 being the cleanest level of air. See the table below from Compressed Air Best Practices for reference:

Class 0 air has more stringent requirements than Class 1 but may be specified differently by various manufacturers and industries. Essentially, class 0 air means there are no contaminants present in the air. This means that the air is also free of any oil aerosols, oil vapors, and oil liquids. This is the highest level of air quality possible.

Grade D Breathing Air

Compressed air can be used to provide clean air to workers for them to be able to perform tasks they would not otherwise be able to perform in the environment without air respirators. OSHA has strict guidelines set in place when it comes to breathing air, to ensure all workers’ health and safety. This OSHA Standard 29 CFR 1910.134(i)(1) is defined clearly in ANSI/Compressed Gas Association Commodity Specification for Air, G-7.1-1989. Grade D is the standard for general industries utilizing air purifying breathing respirators. The following are requirements for Grade D breathing air:

- Oxygen content (v/v) of 19.5% - 23.5%;

- Hydrocarbon (condensed) content of 5 milligrams per cubic meter of air or less;

- Carbon monoxide (CO) content of 10 parts per million (ppm) or less;

- Carbon dioxide (CO2) content of 1,000 ppm or less; and

- Lack of noticeable odor

Visit OSHA’s website to learn more about Grade D breathable air.

Air Treatment & Purification Equipment Options

There are many options to help remove contaminants from your compressor system. Air dryers, filters, oil/water condensate separators, and mist eliminators are a few of the most common options.

Air Dryers

Compressed air dryers are designed to remove moisture from the air. There are a few different types of compressed air dryers that all work to achieve the same result but go about it in different ways. Read our blog post, “Everything Air Dryers,” to learn about air dryers more in-depth.

Filters

There are both downstream and inlet air filters. Inlet air filters are the first line of defense when removing contaminants from entering the airstream. Downstream filters work to clean the already compressed air before it is put to use. These filters are best at catching solid particles but can also remove a moderate amount of water and oil as well.

Oil/Water Condensate Separators

Condensate separators are used to remove oil and water from the compressed air. There are multiple forms of Oil/Water separators, or condensate separators, however, most utilize adsorption to operate. Adsorption is the process in which oil separates from the water and floats to the top due to its lower density. Each condensate separator may have different stages of filtration, but they generally utilize two to three stages to properly separate the oil from the water. The oil residues and condensate are collected and disposed of, while remaining water is discharged from the system.

Mist Eliminators

Mist eliminators are another piece of equipment that utilizes a heavy-duty coalescing filter to remove contaminants from the air. They can remove all types of contaminants, including oil, water/mist, and particulate. When the air hits the mist eliminator, contaminants are blocked or trapped, to become separated from the air passing through. There are three types of mist eliminator types that achieve this goal through different processes, including mesh, vane, and fiber bed.

Air Compressors for Class 0 and Grade D Breathable Air

Oil free air compressors are used when class 0 air is required. This means that there is no oil or lubricant within the compression chamber, and thus cannot enter the air during the compression process. These compressors generally present a higher upfront cost but ensure there is no risk of oil entering into the airstream. Oil free compressors also boast high energy-efficiency, reliable operations, and reduced maintenance costs.

Industries That Rely on High Air Quality

• Food and beverage manufacturing

• Medical facilities and manufacturers

• Pharmaceutical manufacturers

• Cosmetic manufacturers

• High-end painting facilities

• Electronic manufacturers

• Any industries utilizing breathing respirators

How Do I Know If I Have Adequate Air Quality?

Zorn Compressor & Equipment offers air quality testing and audits to ensure you are meeting the necessary air quality requirements specific to your facility and industry. We have local, experienced technicians that will visit your plant, take air samples, and test them for particulate, water/oil, microbial, and grade D breathable air. Once tested, we send the samples to a partner lab to be processed and analyzed. Visit our Air Quality page on our website to learn more.

ZORN'S PROMISE

Zorn is the Midwest leader of custom, engineered compressed air and vacuum solutions. We provide the best customer experience by understanding your applications and needs and offering an unparalleled commitment to customer satisfaction.

Our comprehensive product and service solutions keep you running 24/7.

- Reliable equipment

- Trusted brands

- Seamless, easy installation

- Post-sales support

- Local, 24/7 service

Our compressed air experts look forward to meeting you to discuss your equipment and support needs. Please contact us directly at (262) 695-7000 with any questions or to schedule service for your system moving forward.

Related Resources

- Spring Cleaning Checklist for Compressed Air Systems

- Air Compressor Dew Point 101

- Zorn Compressor Contractor Brochure

- Heat Recovery 101

- Air Compressor Applications in Toy Manufacturing

- How Industrial Air Compressors Are Different

- Trick or Treat: How Compressed Air Gives Us Halloween Candy!

- Technical Solutions Group

- Air Blowers 101

- Air Compressor Cooling Systems 101