Thursday, July 6

All You Need to Know About Rotary Screw & Reciprocating Air Compressors

View Rotary Screw Compressors View All EquipmentRotary Screw Air Compressors

What Is a Rotary Screw Air Compressor?

A rotary screw air compressor is a commonly used compressor in many manufacturing facilities. This type of compressor utilizes rotating spiral screws to reduce the volume of air and compress it for use. They do this by using positive displacement, which is a process that pulls air into the chamber, so that the screws can compress the air.

How Do Rotary Screw Air Compressors Work?

1. Air is pulled into the compression chamber: Using positive displacement, air is pulled into the system through an inlet valve.

2. Air begins to move through the compressor: Moving along the pressure control line, the air will travel through a regulator valve to set the air pressure.

3. If it is an oil-flooded system, oil and air enter the compressor: Oil and air are injected into the compressor and are combined to create a mist.

4. The air is compressed: The air now travels through the rotating spiral screws and gets compressed.

5. Air exits the compressor: The newly pressurized air leaves the compressor and gets moved either to a storage tank or directly to point of use. If it is an oil-flooded system, the air and oil mist leave the compressor and enters and oil separator tank.

If oil-flooded system, these remaining steps take place:

6. The air and oil separate: The oil molecules are brought together by centrifugal force, which causes them to separate and fall to the tank.

7. Oil is filtered out: The system moves the oil to an oil cooler where the oil then travels through a filter to remove any debris or contaminants. The oil then gets recirculated to the air compressor to be used again for the next batch of air.

8. Air is purified: A second filtering process is used as the air travels through a second filter to remove any excess oil or contaminants.

9. Air is ready for use: The now oil free, pressurized air can be moved into a tank for later use or directly to the point-of-use for immediate use.

Common Applications

- Construction Industry

- Demolishing buildings or large structures

- Powering pneumatic tools

- Paving roads

- Manufacturing Industry

- Plastics & rubber

- Injecting & molding

- Metal fabrication

- Power pneumatic tools and assembly stations

- Food & beverage

- Dehydrate ingredients

- Packaging

- Pharmaceutical

- Coat products

- Fill bottles

- Plastics & rubber

- Agriculture Industry

- Powering milking machines

- Transferring dairy products between tanks

- Ventilating greenhouses

- Cleaning irrigation systems

- Powering hand tools

Types of Rotary Screw Air Compressors

Oil Lubricated vs. Oil-Free

Oil lubricated and oil-free are the two main categories rotary screw compressors get grouped into. Oil lubricated models utilize lubricants, like oil, in the compressor chamber to both cool and lubricate the compressor element. This lubricant also helps form a seal that can cause a noise-dampening effect- generally allowing a quieter operation. Oil-free compressors require NO oil in the compression chamber, and thus produce purer air for more industries that require no risk of contaminants entering the air stream- like medical or food & beverage. Under both these categories, you can find a few different configurations:

Base-Mounted: standalone units that provide a contestant flow of air and have minimal space requirements.

Tank-Mounted: mounted units on top of an air receiver tank to store compressed air.

Total System: units that combine features of base- and tank-mounted compressors to save space and efficiently provide pure air.

Variable Speed: Units with motor control drives that regulate the speed of the system to offer energy efficiency benefits.

Benefits of a Rotary Screw Air Compressor

- Less frequent maintenance compared to other types of compressors due to less parts.

- Functions under extreme temperatures and environmental conditions.

- Energy efficient by producing less heat, having an efficient design, and utilizing less oil.

- Has multiple options for sizes, technologies, specific applications, etc.

- Ability to produce high volumes of compressed air continuously and consistently.

- Cleaner air with very little oil carryover

- Quieter when operating compared to other compressor options.

Disadvantages of Rotary Screw Air Compressors

- Specific Maintenance Requirements: Rotary screw compressors have very detailed and unique systems that require special maintenance. A compressed air expert and certified technician is highly recommended when conducting any kind of maintenance or repair. However, rotary screw compressors generally require less maintenance in comparison to other types of compressors.

- Price: The initial cost to buy a rotary screw air compressor is more of an investment that most other types. However, the high efficiencies and less maintenance creates a lower continuous cost overtime.

Maintenance Requirements

- Draining excess fluid

- Checking & replacing oil

- Cleaning and replacing filters

- Changing the oil/water separator

- Inspecting belts & drives

- Maintaining coolers & heat exchangers

- General cleaning of compressor & environment

Reciprocating Air Compressors

What Is a Reciprocating Air Compressor?

Reciprocating air compressors are positive-displacement machines that utilize a piston and cylinder to compress the air.

How Do Reciprocating Air Compressors Work?

The crankshaft driven piston is used to decrease the amount of space the air is taking up and pressurize the air once it enters the chamber.

In a single-stage reciprocating compressor these steps are taken:

1. Air is drawn into the cylinder through the intake valve.

2. The piston pulls away from the intake valve and allows the air to pass into the cylinders.

3. The crankshaft powers the piston, which compresses the air in one stroke where it can then be sent either to the point of use or to a storage tank for later use.

A two-stage reciprocating compressor, requires these addition steps:

4. Air travels to a second cylinder where a second piston compresses the air further.

5. Compressed air gets sent either to the point of use or to a storage tank for later use.

Common Applications

- Manufacturing Industry

- Powering air tools

- Sandblasting

- Packaging

- Metals Industry

- Welding/cutting

- Powering air tools

- Molding

- Automotive Industry

- Spray painting vehicles

- Autobody sanding

- Agriculture Industry

- Conveying feed/grains between silos

- Crop spraying

- Powering dairy machines

Types of Reciprocating Air Compressors

Single-Acting: basic reciprocating machine that is spring-loaded and includes one way inlet & discharge valves. These machines only have one compression cycle for each crankshaft turn.

Double-Acting: reciprocating machine that includes inlet valves on both sides of the cylinder and has two compression cycles for each crankshaft turn. This is a very efficient machine that generally is found in higher horsepower options.

Diaphragm: reciprocating machine also known as a membrane compressor. This kind of unit utilizes a rotating membrane to pull air into the system. Two systems are used within this kind of reciprocating compressor: hydraulic system and air pressure system.

Benefits of a Reciprocating Air Compressor

- High pressure & power when needed

- Intermittent Usage Capabilities

- Lower initial cost

- Smaller design

- Simpler maintenance due to more basic internal parts

Disadvantages of Reciprocating Air Compressors

- More frequent maintenance requirements for compressor and its many components, however, parts are less expensive compared to a rotary screw.

- More friction and therefore more heat production

- Louder operations

Maintenance Requirements

- Maintain and replace lubricant

- Drain tanks and valves of excess moisture

- Monitor and maintain pistons

- Check for excess noise or vibration

- Inspect belts & internal components

- Clean cooling surfaces, compressor, & environment

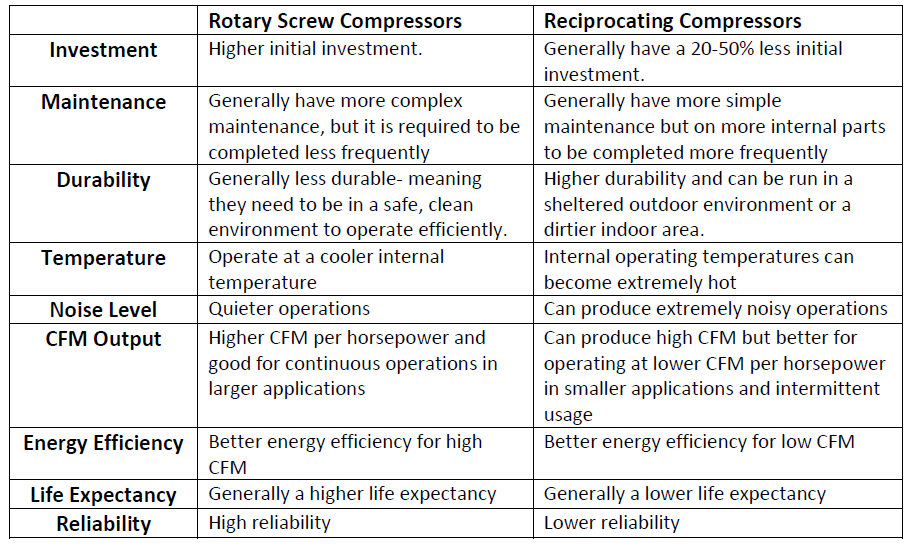

Rotary Screw vs. Reciprocating

Both rotary screw and reciprocating machines are great air compressors. The advantage of one over the other depends entirely on your applications for your facility. A rotary screw air compressor is considered the “workhorse” of the industry, meaning it is meant to provide continuous air at full capacity for larger operations. They also produce cleaner air so they can be the preferred choice for industries with high air-quality standards. Reciprocating compressors are better for intermittent usage for smaller applications requiring short bursts of air. This type of compressor does not have to be operated at maximum capacity but should generally be sized larger than necessary to make room for growth and avoid excessive heat generation that can cause wear and tear.

Below is a table summarizing the differences of the two compressors:

ZORN'S PROMISE

Zorn is the Midwest leader of custom, engineered compressed air and vacuum solutions. We provide the best customer experience by understanding your applications and needs and offering an unparalleled commitment to customer satisfaction.

Our comprehensive product and service solutions keep you running 24/7.

- Reliable equipment

- Trusted brands

- Seamless, easy installation

- Post-sales support

- Local, 24/7 service

Our compressed air experts look forward to meeting you to discuss your equipment and support needs. Please contact us directly at (262) 695-7000 with any questions or to schedule service for your system moving forward.

Related Resources

- Spring Cleaning Checklist for Compressed Air Systems

- Air Compressor Dew Point 101

- Zorn Compressor Contractor Brochure

- Heat Recovery 101

- Air Compressor Applications in Toy Manufacturing

- How Industrial Air Compressors Are Different

- Trick or Treat: How Compressed Air Gives Us Halloween Candy!

- Technical Solutions Group

- Air Blowers 101

- Air Compressor Cooling Systems 101